In our pursuit to provide process and quality engineers with the most powerful tool to fix issues faster, to get ahead of new issues before they impact production, and to secure greater bandwidth and deep focus to find new ways to improve their process efficiencies – Fero Alerts are at the core of this solution.

Relieving the burden of constant production monitoring and surprise issues, Fero Alerts provide real-time insight into production conditions and anomalies that supply the peace of mind needed to address tasks faster and resolve anomalies before they impact production.

Before Fero, a day in the life of an industrial engineer was heavily fragmented and reactive. Their time was constantly rerouted to fix unexpected production issues that occurred, to monitor that their solutions are working, and to troubleshoot potential triggers that could cause further disruption.

With the recent release of our explainable Fero live production alerts, engineers and operators are relieved of the function of constant production monitoring and disruptions whilst accessing greater insight into live production conditions than ever before.

What are Fero Alerts?

Fero Alerts are explicit and concise alerts that are pushed to engineers to keep them aware of changing production conditions and anomalies that may need to be addressed, and to expedite next steps.

Typical Fero Live Production Alerts

Fero Out of Specification Alert

When a tag has a new out-of-spec measurement, the engineer will be alerted of which value is out of spec, and what the acceptable spec range is defined as, which expedites next steps.

Example: If one of your quality metrics is the viscosity of your production, you need to make sure these readings are within your specifications. You will receive an alert notification any time your viscosity is higher or lower than your specs so you can intervene before your quality is adversely affected.

Fero Risk Prediction Summary Alert

Once deployed, Fero’s AI will continuously make predictions regarding the future state of your factory. Fero will send a daily report of alerts based on these predictions, broken down by risk level. These highlight potential future problems before they occur so your team can stay ahead of issues to reduce risk in your factory.

Example: If tensile strength is a quality parameter that you care about, Fero’s Risk Prediction Summary will give you a report of all batches in the previous day that risk failing their quality tests. This report can streamline shift changeover and work prioritization.

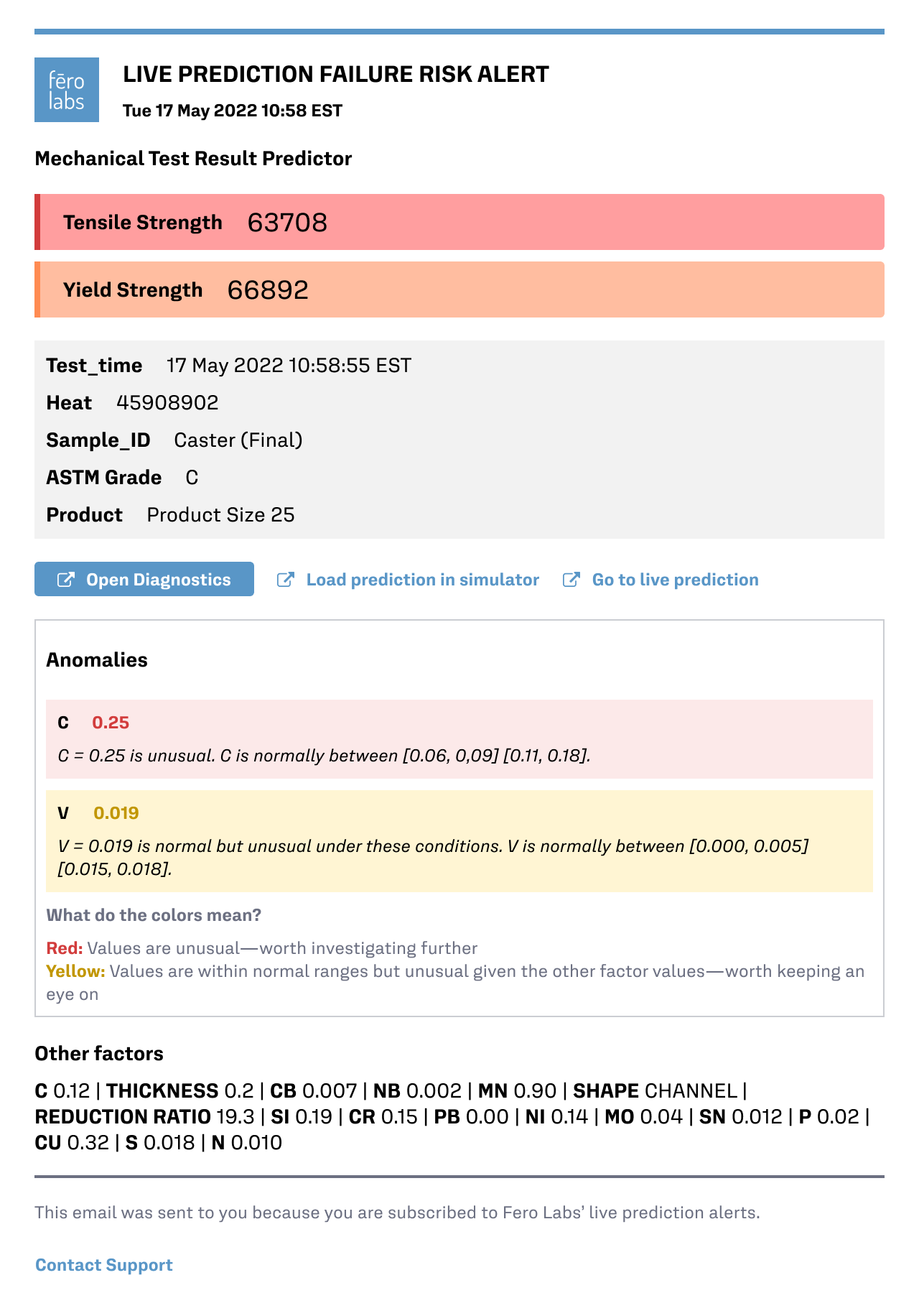

Fero Failure Risk Alert

This alert will be pushed when Fero AI predicts that a quality KPI (such as, Tensile Strength) risks being out of specifications. The alert goes beyond highlighting a potential risk, it provides all the context the engineer will need to understand how to prioritize the potential risk and what to do next. Color coding indicates at a glance what will require immediate attention versus what is worth keeping an eye on.

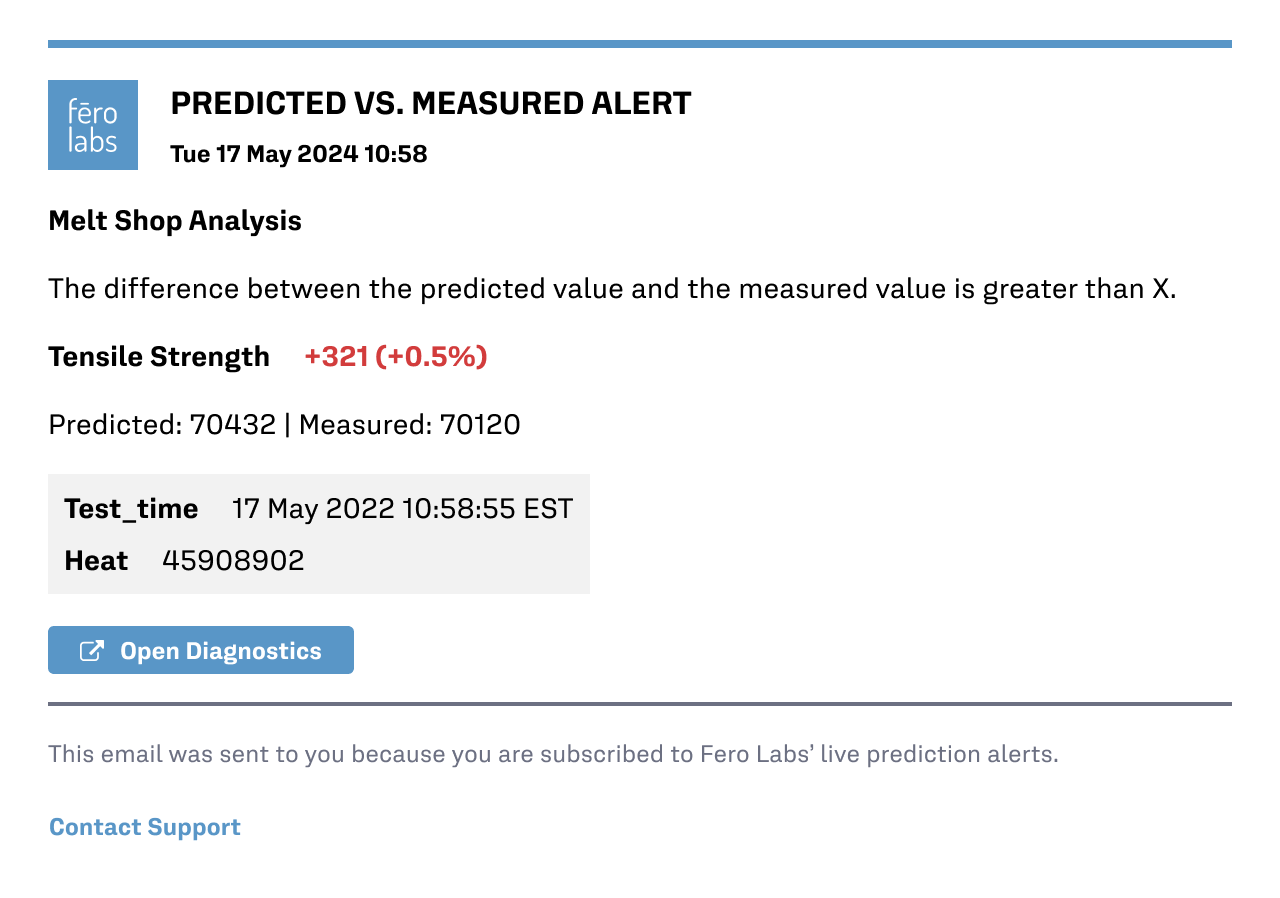

Fero Predicted vs. Measured Alert

This alert complements the Fero Failure Risk Alert and Fero Risk Prediction Summary Alert to add an additional layer of confidence that everything is operating as expected in the plant. When a KPI measurement becomes available Fero compares this reading with its own prediction. If the difference between the two is larger than a threshold, an alert is sent to the relevant engineers. This measurement is valuable for surfacing measurement errors at your lab or sensor drift for in-line analyzers.

Example: The Tensile Strength measurement deviates more than usual from Fero's prediction. Receiving this alert enables you to flag this test reading as "problematic" and redo it to be certain of the result.

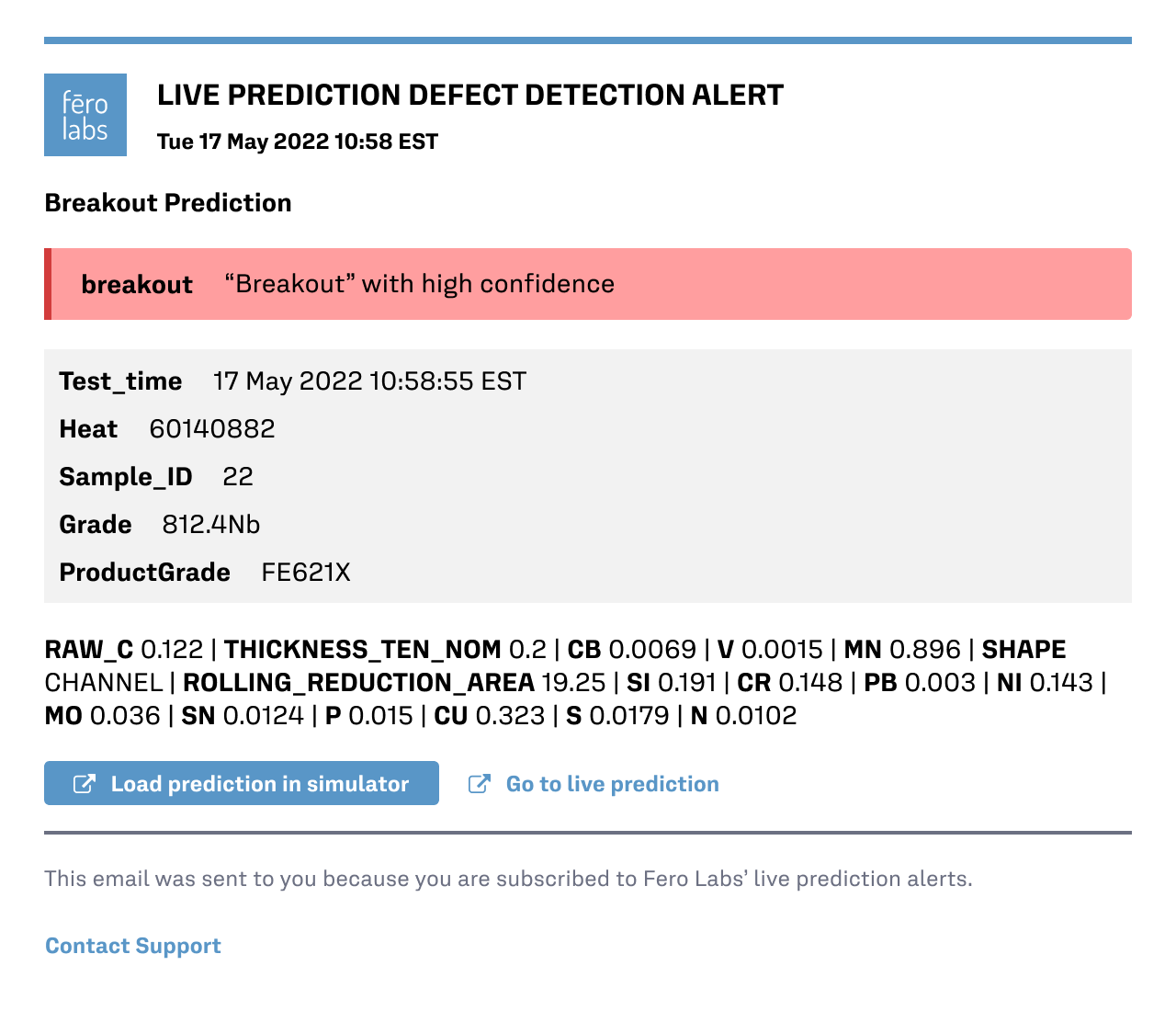

Fero Defect Detection Alert

This alert will be especially important for quality engineers to get ahead of potential issues that could cause defects. The alert is sent when Fero AI predicts a defect and provides all the critical batch and spec information that the engineer will need in order to know what step to take next. Additional numerical KPI alerts are also available to monitor changes in quality or production volume.

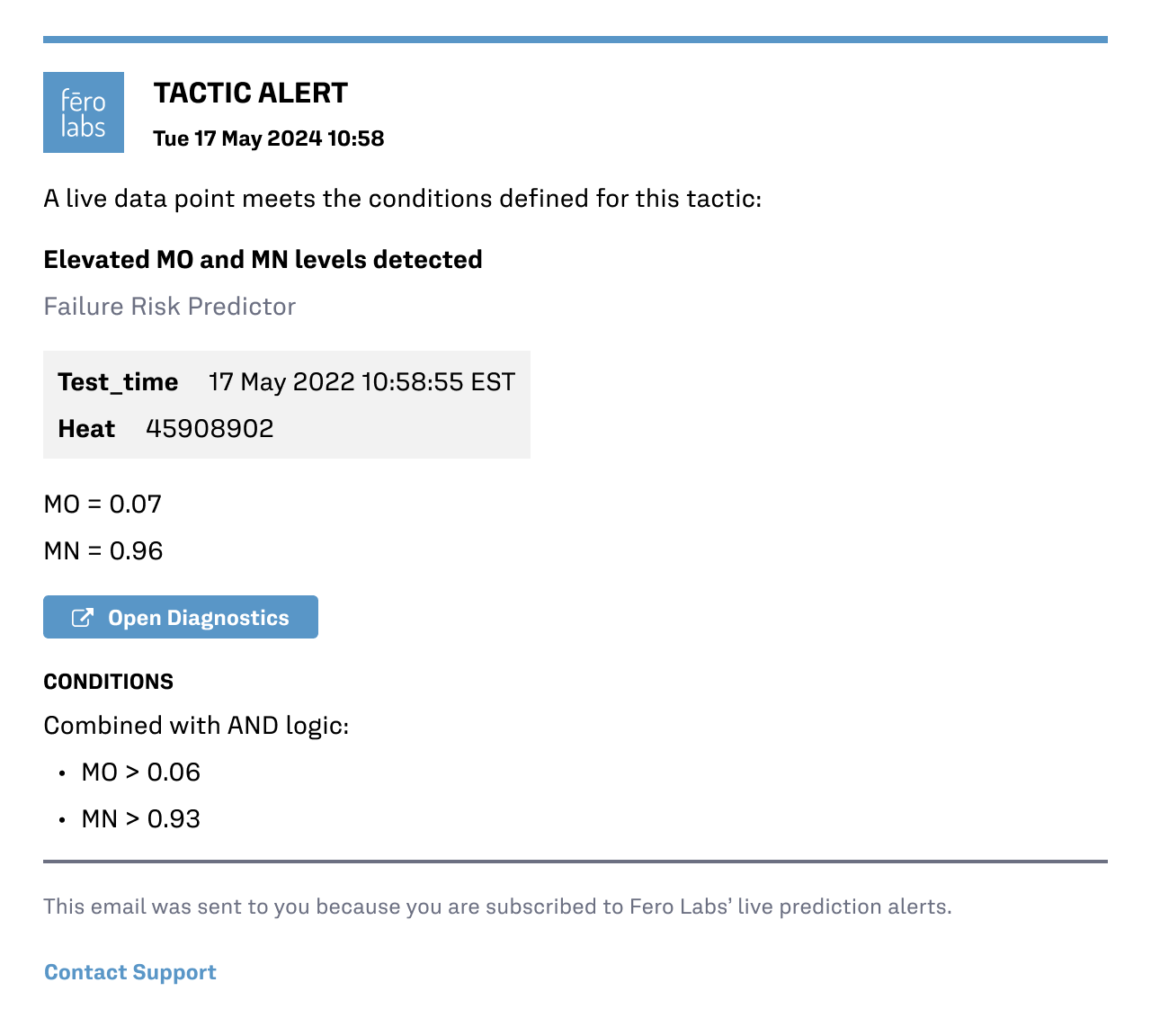

Fero Tactic Alert

A Tactic in the Fero software captures a set of operating procedures that are sent to the control room under a set of plant conditions. The Tactic Alert notifies engineers that conditions triggered a set of operating procedures in the pulpit. This way, engineers are always kept in the loop as to what is happening in the plant.

Example: Assume that an engineer decided that the reactor temperature will be set to a pre-decided value any time the flow rate is within a range. This is defined as a Tactic. By attaching an alert, they will be notified that the flow rate has entered that range and therefore that the operator was notified to set the reactor temperature.

At a time when the manufacturing sector is facing its greatest worker and skill shortage, maximizing worker productivity and peace of mind is essential to ensure operational efficiency and to minimize worker burnout. Traditional production and diagnostics tools are no longer adequate.

If you want to support your team and production better in 2025, please reach out to my team to learn about our Profitable Sustainability Platform. Providing the most powerful diagnostics to pinpoint root causes faster, explainable predictions and recommendations to ensure workers know what to do next, and dynamic process optimization supported by explainable Fero Alerts.