Use Case Description

Background

Flares are an important safety feature for oil and gas process units such as refineries, pipelines and storage vessels, as well as in certain chemical facilities.

Refineries deploy flares to relieve pressure in production systems and to safely dispose of excess flammable waste gases under normal operations, as well as during startup and shutdown.

Incomplete flaring is a leading cause of methane emissions in refinery operations. As such, flaring activities are subject to strict regulation with specific limits for net heating value (NHV), combustion efficiency (CE), and destruction and removal efficiency (DRE) of the flare. To adhere to these regulatory standards, manufacturing facilities and refineries must closely monitor and adjust combustion parameters to ensure compliance.

Problem

Flaring performance can be affected by many factors such as gas composition, flow rates, atmospheric conditions, and flow rates of steam and fuel used to assist in combustion. Furthermore, the operational stage of the flaring activity, whether during normal operation, startup, shutdown, or even malfunction can also affect its performance.

Understanding the interplay of these factors and assuring compliant flaring is a complex task. Plant operators and managers need to effectively oversee combustion efficiency to mitigate periods of excessive pollution or greenhouse gas emissions, thereby avoiding potential fines from regulatory agencies. Additionally, inefficient flaring due to suboptimal use of steam and supplemental gas, can lead to unnecessary operational expenses.

Monitor variations in process conditions and accurately predict flare gas combustion efficiency. Proactively recommend actions to ensure that variations do not adversely affect flaring performance.

A key aspect of controlling flaring performance lies in knowing the chemical composition of the gas being flared. Gas chromatograph and mass spectrometer measurements of the flow gas provide this information. However, these methods can encounter issues such as inaccuracies or need for periodic maintenance, necessitating additional lab measurements for confirmation.

Being able to predict combustion efficiency in real-time with a well-calibrated virtual soft sensor enables operators to better manage and optimize flaring performance and helps bridge the gap in information caused by any equipment downtime or lab testing delays, ensuring more reliable and efficient flaring operations.

Fero Labs Solution

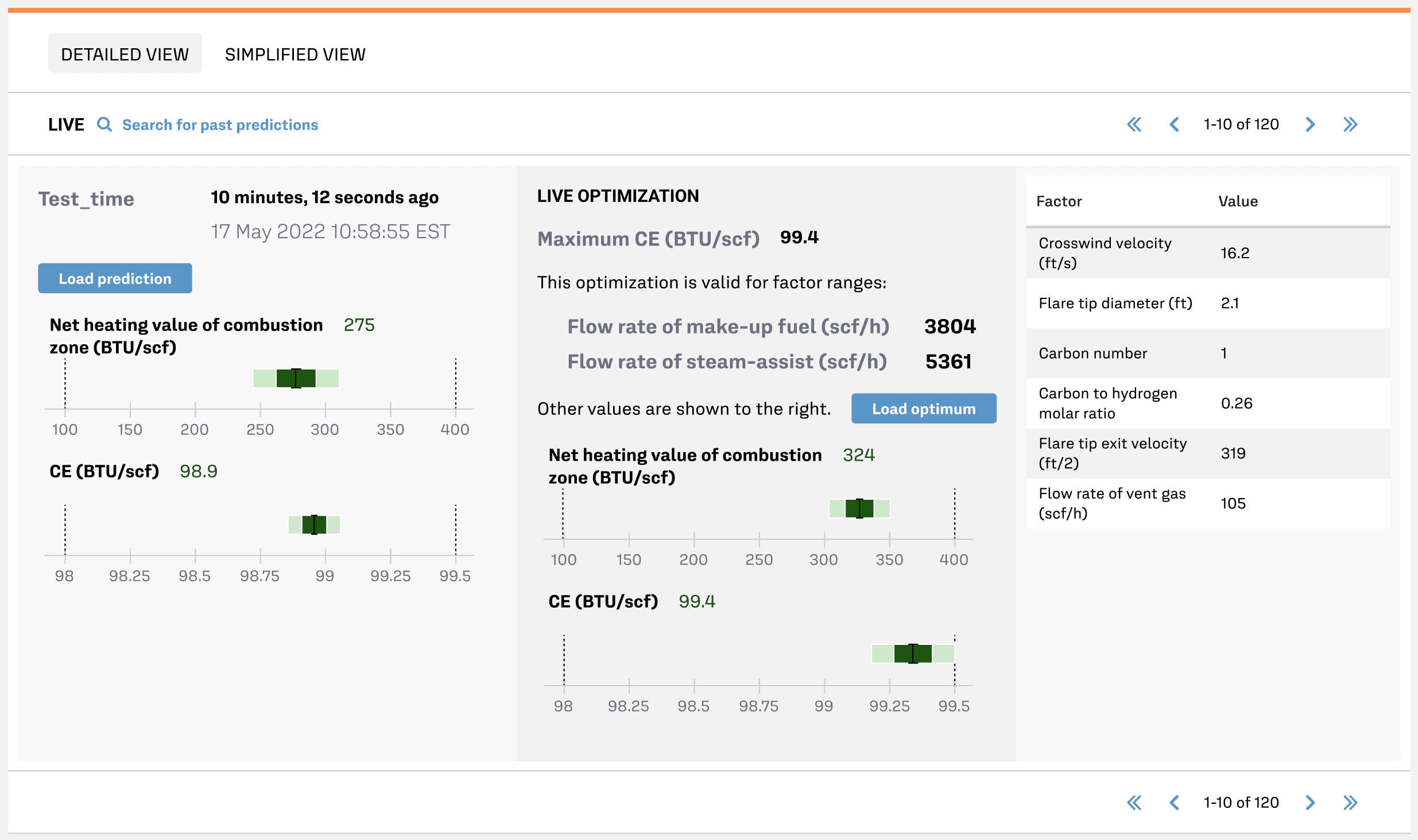

Plant engineers can configure a virtual soft-sensor to predict and monitor “hard-to-measure” flaring performance quality measures in real-time. This soft-sensor equips operators with real-time insights into the NHV of combustion zone and CE of flare gas, helping them to monitor whether their combustion and emissions quality related parameters meet industry specifications. Furthermore, soft sensors are instrumental for detecting ongoing combustion efficiency issues. Such insight is critical in guiding operators to make informed decisions on whether to change operational process parameters or initiate maintenance protocol or a shutdown.

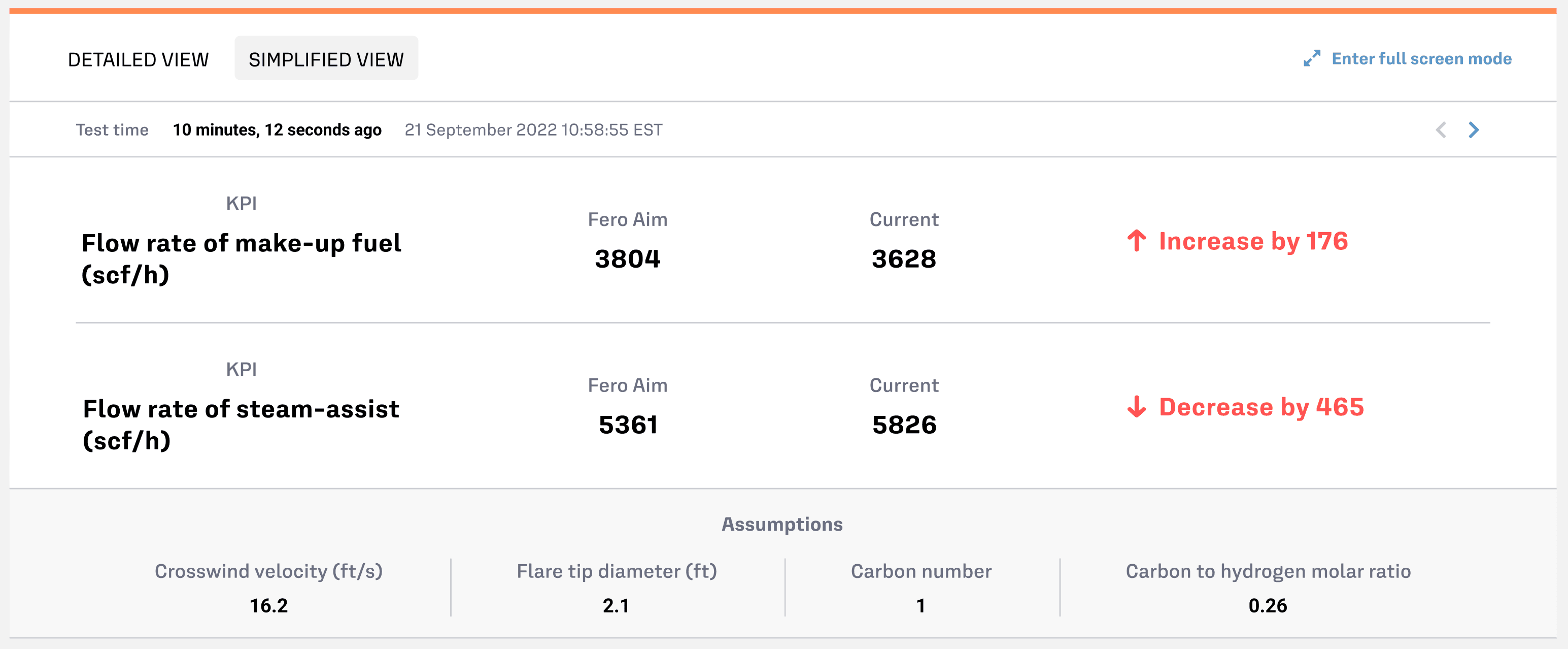

A Live Fero Analysis for this use case presents two screens:

- Detailed View: for production and control engineers to monitor production and follow Fero recommended actions at any moment.

- Simplified View: for plant operators with critical information clearly presented.

Process & Business Outcomes

Real-time monitoring of combustion efficiency

Operators can gain real-time, continuous insights into combustion efficiency and proactively prevent significant issues from arising. Expert operators also gain direct root-cause insights into how operational actions, such as changes in flow rates, or environmental conditions can affect CE.

In-process optimization to reduce Scope 1 emissions

By controlling for steam and make-up gas consumption, Fero’s optimizer enables refineries to maximize the combustion efficiencies for flaring while keeping NHV within spec. This, in turn, contributes to a direct reduction in Scope 1 emissions and also enables refineries to contribute towards their emissions targets while minimizing any associated carbon taxes.

With full adoption of Fero, plant operators can also expect up to a 7% reduction in fugitive emissions from flaring. Fero can provide reporting capabilities that directly track and account for this reduction.

Steam-assist and make-up gas cost reduction

When NHVs of the operating zone fall below spec, the flaring process typically requires the addition of makeup gas and steam-assist. Fero’s optimizer is designed to offer precise recommendations that ensure NHV levels meet the required specification. This will help avoid the excessive use of steam and makeup gas, leading to a reduction in operational costs.

With full adoption of Fero Las, plant operators can also expect up to 76% reduction in steam and make-up gas consumption.

Fero Labs Adoption Timeline

Plant teams can collaborate to set up and deploy Fero Labs. Below is a timeline highlighting typical steps. With Fero’s easy-to-use, no-code interface, this can be achieved in a matter of weeks, not months or years.

Data Requirements

Plant teams can collaborate to set up and deploy Fero. Below is a timeline highlighting typical steps. With Fero’s easy-to-use, no-code interface, this can be achieved in a matter of weeks, not months or years.

Activating This Use Case

Consider our Industrial Use Case Playbooks as inspiration and tactical ideas for your team to align on to maximize the efficiencies of your plant.

Each Playbook has a matching Use Case Blueprint which provides more detailed steps to activate each use case within the Fero Labs platform.

If you’re curious to see these in action please book a free feasibility study with our team!

Together, let us continue to push the boundaries of what's possible, driving towards a future where industrial manufacturing is not just efficient and sustainable but truly transformative in its impact on society and the world at large.

Thank you for joining us on this journey, and we look forward to continuing to partner with you in your pursuit of excellence.

Download the entire Flare Emissions Minimization Playbook to access additional tables and details about this industrial use case.